Make: CMI / TEREX

Size: Drum Factory Rated @ 500 TPH

Type: 400–500 TPH Semi-Portable Counterflow Drum Plant

**Cold Feed System**

CMI Seven (7) Bin 10' x 14' Stationary Cold Feed System

Nominal 30" wide feeders with 5 HP AC drives

Nominal 30" wide integral collecting conveyor with folding head section

Full-length walkway with steps for accessibility

Bins relined with AR plate

No-flow switches, tachometers, and positive lock gates

Bin dividers to help keep heaped material separated

**Scalping Screen**

5' x 10' single-deck Virgin Aggregate Scalping Screen

10 HP drive

**Virgin Scale Conveyor**

Portable CMI 30" x 50' long Virgin Scale Conveyor

Receiving trough and belt scale

Mounted on single-axle suspension (scalping screen located on same frame)

**Drum**

2014 Terex Model #E3-500S Stationary High Recycle Counterflow Drum

New flights and liners 2024

15' slinger feed conveyor

Trunnion driven with (4) 50 HP motors and heavy-duty Dodge TXT 8 reducers

Hauck StarJet 750 burner set up on natural gas with gas train

Recycle entry collar, dust injection screw conveyor, and support stands

Average shell thickness: .490"

Primary Collector

Vertical stationary cyclone with dust return via auger to drum recycle entry

Heavy-duty independent support structure

**Baghouse**

Portable CMI Model #RA-418P Roto-Aire Baghouse

Over 18,000 sq. ft. of cloth

Factory rated @ 85,000 ACFM

Mounted fan with twin 100 HP drives

Dual auger dust removal (bottom-mounted)

Triple-axle suspension (no rims on tires)

Dust / Lime Silo

2009 Terex self-erect, nominal 500 BBL

Weigh pod, air lock, load cells, and controls included

Top-mounted filter vent

Tandem-axle portable with 60 HP Gardner Denver blower

**AC Tanks**

(1) CMI portable 2-compartment 30,000-gallon coiled AC tank

Gooseneck-mounted CEI 2 MBTU combo fuel hot oil heater

Rear-mounted 3" metering skid with flow meters

Light coking — empty (tandem axle, no tires or rims)

was professionally cleaned out winter 2022

**(1)** Portable 30,000-gallon coiled AC tank with (3) top-mounted agitators

Light coking — empty (tandem axle, no tires or rims)

**(1)** Portable 20,000-gallon coiled AC tank

Light coking, small residual material (but empty)

Tandem axle (tires, no rims)

**(1)** Portable 35,000-gallon coiled AC tank with (3) top-mounted agitators

Surplus 3" metering skid

Light coking — empty (tandem axle, no tires or rims)

**Recycle System**

CMI Two (2) Bin 10' x 14' Stationary Recycle System

Nominal 30" wide feeders with 5 HP AC drives

30" wide integral collecting conveyor with folding head section

Full-length walkway with ladder access

Equipped with vibrators and air cannons

Includes 5' x 10' single-deck scalping screen

Stationary CMI conveyor with belt scale and gravity take-up feeding into recycle collar (heavy-duty truss frame)

**Silo System**

Three (3) CMI nominal 210-ton silos, silo 2 new cone liners

30" single-chain main drag slat conveyor

33" x 51" oil-heated box floor with booster pump package

Low-point reject chute

75 HP motor with Rex reducer

(2) CMI DC3017 dual-chain oil-heated transfer conveyors (30" x 17')

Driven by 30 HP motors with Dodge reducers

4-section 80' above-ground steel truck scale

**(All 3 silos are empty)**

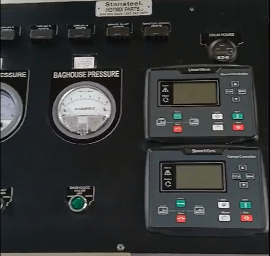

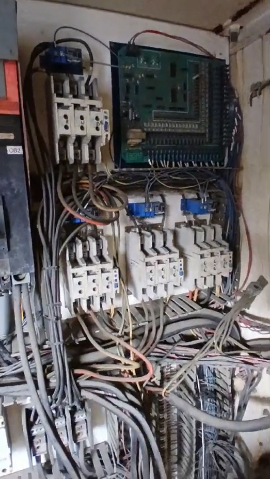

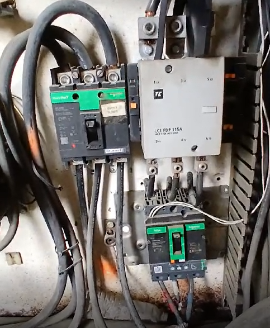

**Controls & Electrical**

Stationary CMI control house with heating and air conditioning

April 2024 Minds plant controls, CMC Auotomation, All PLC based

CMI Energy Center complete with AC and soft starts for burner, blower, and drum

Balance of starters in individual buckets

1,200 amp main

**ADDITIONAL NOTES**

Plant is in very good condition with many upgrades

Spare parts included (stored in two conex boxes)

Two compressors included

Some components portable, but silo package, cold feed, and RAP systems are stationary

Drum on portable frame with kingpin plate (no axles or erection gear)

Baghouse bags and ductwork in good condition

Drum shell thickness and flights in good condition (one row of mixing flights needs attention)

Silo and cold feed system appear to be in very good condition

The Drum Has 6 Access Panels